| Headings | Sub-Topics |

|---|---|

| Introduction | Overview of Galvanized Angle Boots |

| What is a Galvanized Angle Boot? | Definition and Purpose |

| History of HVAC Components | Evolution and Innovations |

| Benefits of Galvanized Angle Boots | Durability, Corrosion Resistance, Versatility |

| Types of Galvanized Angle Boots | Designs, Sizes, Applications |

| Materials Used in Galvanized Angle Boots | Galvanization Process, Steel Grades |

| How to Choose the Right Galvanized Angle Boot | Considerations and Tips |

| Installation Guide for Galvanized Angle Boots | Step-by-Step Instructions |

| Maintaining Your Galvanized Angle Boot | Cleaning, Repairs, Longevity |

| Common Issues and Solutions | Troubleshooting Tips |

| Comparing Galvanized Angle Boots to Other HVAC Boots | Metal vs. Plastic, Insulated vs. Non-Insulated |

| Eco-Friendly Aspects of Galvanized Angle Boots | Sustainability, Recyclability |

| Cost Analysis of Galvanized Angle Boots | Budgeting, Cost vs. Value |

| Custom Galvanized Angle Boots | Customization Options, Benefits |

| Best Practices for HVAC Efficiency | Placement, Design Impact |

| Enhancing HVAC Systems with Galvanized Angle Boots | Design Tips, System Integration |

| Innovations in Galvanized Angle Boots | Latest Trends and Technologies |

| Frequently Asked Questions (FAQs) | Common Questions and Answers |

| Conclusion | Summary and Final Thoughts |

Galvanized Angle Boot: A Complete Guide

SEO Meta-Description: Discover the comprehensive guide to Galvanized Angle Boots, including benefits, installation, maintenance, and tips for choosing the perfect angle boot for your HVAC system.

Introduction

In HVAC systems, proper airflow and efficient ductwork connections are crucial for maintaining optimal performance. Among the essential components, the Galvanized Angle Boot stands out for its durability and corrosion resistance. This article explores everything you need to know about galvanized angle boots, from their history and benefits to installation and maintenance tips.

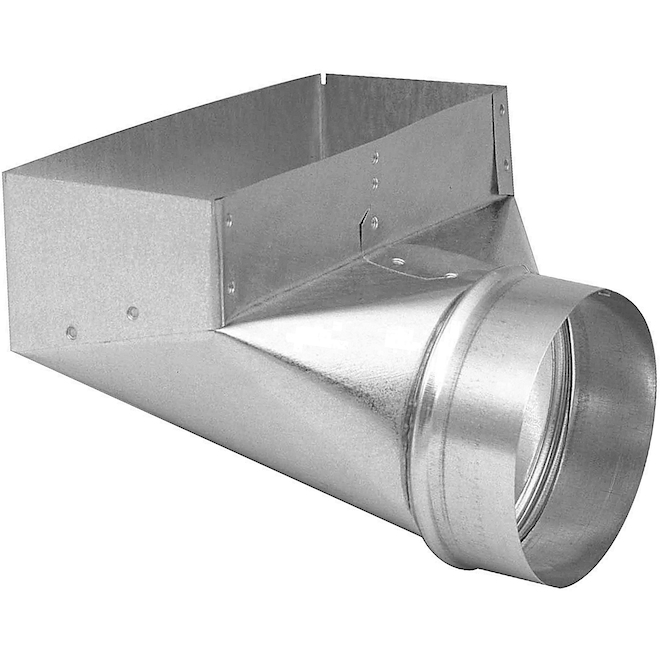

What is a Galvanized Angle Boot?

A Galvanized Angle Boot is an HVAC component used to connect ducts at specific angles, facilitating smooth airflow and efficient ventilation. Made from galvanized steel, these angle boots are designed to resist corrosion and provide long-lasting performance. They come in various sizes and configurations to meet different HVAC requirements.

History of HVAC Components

The development of HVAC components has evolved significantly over the years. Initially, ductwork and fittings were made from basic materials like clay or wood. With the advent of metalworking, steel and other metals became the standard due to their durability and strength. Galvanized angle boots, in particular, emerged as a reliable solution for creating angled connections in duct systems, enhancing airflow and system efficiency.

Benefits of Galvanized Angle Boots

Durability: Galvanized steel provides excellent strength and durability, ensuring the angle boots can withstand the rigors of HVAC systems.

Corrosion Resistance: The galvanization process coats the steel with a layer of zinc, protecting it from rust and corrosion.

Versatility: Available in various sizes and angles, galvanized angle boots can be used in a wide range of HVAC applications.

Types of Galvanized Angle Boots

There are several types of galvanized angle boots, each designed for specific needs:

- Standard Angle Boots: Commonly used for typical HVAC installations, available in standard angles like 45° and 90°.

- Custom Angle Boots: Made to order for unique angles and specific HVAC system requirements.

- Adjustable Angle Boots: Feature adjustable joints to accommodate various installation angles.

Materials Used in Galvanized Angle Boots

Galvanization Process: Galvanized angle boots are made from steel that has undergone a galvanization process, where the steel is coated with zinc to prevent corrosion.

Steel Grades: Common steel grades used include galvanized mild steel and galvanized stainless steel, chosen for their strength and resistance to environmental factors.

How to Choose the Right Galvanized Angle Boot

When selecting a galvanized angle boot, consider the following factors:

- Size: Ensure the angle boot fits the duct dimensions and meets the airflow requirements.

- Angle: Choose the correct angle (e.g., 45°, 90°) for your specific ductwork configuration.

- Material: Select a steel grade that suits the environmental conditions and expected wear.

- Adjustability: Consider adjustable angle boots if flexibility is required during installation.

Installation Guide for Galvanized Angle Boots

Installing a galvanized angle boot involves several steps. Follow these guidelines:

- Measure the Duct Path: Plan the layout and measure the length and angles of the duct path.

- Cut the Ducts: Cut the ducts to the required lengths, ensuring clean, straight edges.

- Attach the Angle Boot: Insert the angle boot into the duct ends, ensuring a snug fit.

- Secure the Connections: Use sheet metal screws or duct tape to secure the angle boot to the ducts.

- Seal the Joints: Apply duct mastic or foil tape to seal all joints and connections, preventing air leaks.

Maintaining Your Galvanized Angle Boot

Proper maintenance can extend the life of your galvanized angle boot and ensure optimal performance. Here are some tips:

- Regular Inspections: Periodically inspect the angle boot for signs of damage, rust, or leaks.

- Cleaning: Clean the angle boot and ducts regularly to remove dust and debris that can obstruct airflow.

- Repairs: Address any damage or wear promptly to maintain efficiency and prevent further issues.

Common Issues and Solutions

Air Leaks: Seal any leaks with duct mastic or foil tape to maintain airtight connections.

Corrosion: Check for signs of rust and apply a rust-inhibiting primer or paint if needed.

Blocked Airflow: Clean the ducts regularly to remove any obstructions that could hinder airflow.

Comparing Galvanized Angle Boots to Other HVAC Boots

Metal vs. Plastic

- Durability: Metal angle boots, especially galvanized ones, are more durable than plastic ones.

- Corrosion Resistance: Galvanized metal is resistant to corrosion, while plastic can degrade over time.

Insulated vs. Non-Insulated

- Thermal Efficiency: Insulated angle boots provide better thermal efficiency by reducing heat loss.

- Condensation Prevention: Insulated boots help prevent condensation, reducing the risk of mold growth.

Eco-Friendly Aspects of Galvanized Angle Boots

Sustainability: Galvanized steel is recyclable, reducing environmental impact.

Energy Efficiency: Properly installed angle boots improve HVAC system efficiency, lowering energy consumption and greenhouse gas emissions.

Cost Analysis of Galvanized Angle Boots

Initial Cost: Galvanized angle boots may have a higher upfront cost compared to non-galvanized or plastic options, but their benefits often outweigh the initial investment.

Maintenance Cost: Regular maintenance can be minimal, reducing long-term costs.

Value: The durability and efficiency provided by galvanized angle boots offer excellent value over time.

Custom Galvanized Angle Boots

Customization options allow for tailored solutions to meet specific HVAC requirements. Benefits of custom galvanized angle boots include:

- Unique Sizes: Angle boots made to fit non-standard dimensions perfectly.

- Specific Angles: Customized angles for unique ductwork configurations.

- Enhanced Durability: Tailored materials and coatings for better performance in harsh environments.

Best Practices for HVAC Efficiency

Optimal Placement: Position angle boots strategically to ensure even airflow distribution and minimize energy loss.

Design Considerations: Choose designs that facilitate unobstructed airflow and easy maintenance.

Regular Maintenance: Keep angle boots clean and well-maintained to ensure optimal HVAC system performance.

Enhancing HVAC Systems with Galvanized Angle Boots

Galvanized angle boots can significantly enhance HVAC system performance by providing reliable and durable connections. Here are some design tips:

- Strategic Placement: Place angle boots in areas that optimize airflow and minimize energy loss.

- Quality Materials: Invest in high-quality galvanized steel to ensure long-term performance.

- Regular Upgrades: Periodically upgrade or replace old angle boots to maintain efficiency and comfort.

Innovations in Galvanized Angle Boots

Recent advancements in galvanized angle boot design and manufacturing include:

- Smart Angle Boots: Integrating technology for automated control and monitoring of airflow and temperature.

- Advanced Coatings: New coatings that provide better corrosion resistance and durability.

- Eco-Friendly Options: Use of sustainable and recyclable materials in production.

Frequently Asked Questions (FAQs)

What materials are used in galvanized angle boots? Galvanized angle boots are typically made from galvanized steel, which is steel coated with a layer of zinc to prevent corrosion.

How do I clean galvanized angle boots? Clean galvanized angle boots by removing dust and debris with a damp cloth. For a deeper clean, professional duct cleaning services are recommended.

Are galvanized angle boots expensive? Galvanized angle boots may have a higher initial cost compared to non-galvanized or plastic options, but they offer long-term savings through improved durability and reduced maintenance needs.

Can galvanized angle boots be customized? Yes, many manufacturers offer customization options for size, angle, and finish to suit individual HVAC system requirements.

How do I choose the right size angle boot? Measure the duct dimensions and angles to ensure the angle boot fits correctly. Consider the overall design.